The Importance of Data to Fleet Electrification

This is one in a series of blog posts exploring the role of data in fleet electrification.

How do commercial fleets strive to achieve efficiency?

Efficient fleet operations rely on minimising downtime and having a plan B when plan A fails. They also rely on all elements of the operation communicating with each other so that no link in the chain breaks. Customer fulfilment relies on a joined-up system of predictable outcomes, with improvements achieved by addressing inefficiencies, for example utilising loading/ unloading time and refining optimisation tools for route planning and/ or last-mile delivery. Return on investment relies on internal processes being combined into a coherent system solution across the entire organisation.

How does fleet electrification change this?

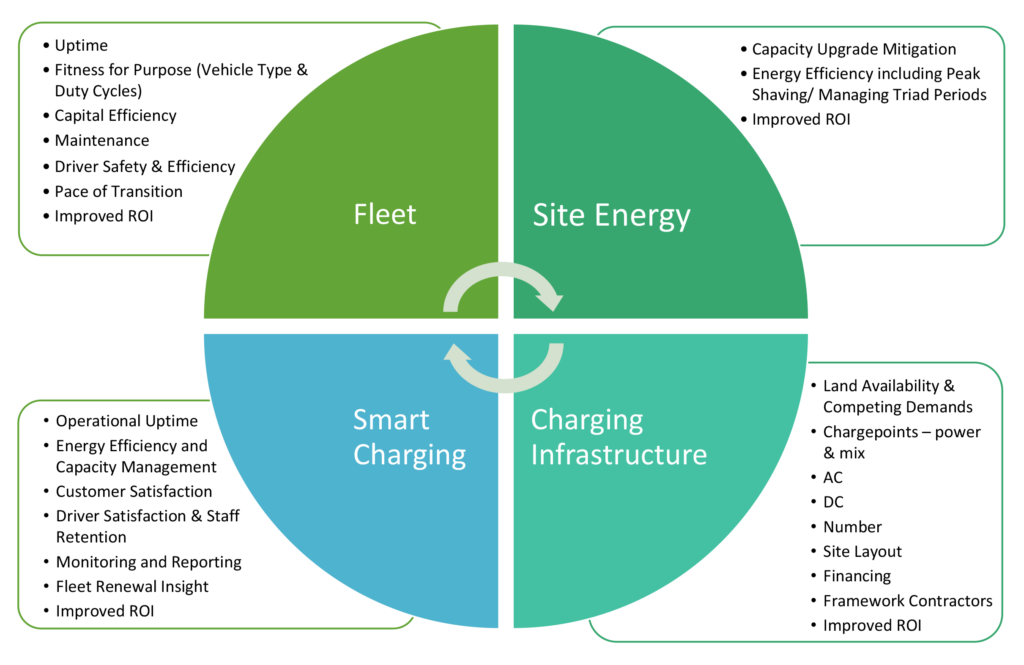

The simple answer is that the objectives remain the same. The big shift that becomes apparent with EVs, however, is the equation between capital cost and utilisation. Historically many commercial fleets have operated with high levels of under-utilisation. The process of electrifying a commercial fleet introduces the opportunity for fleets to right-size procurement (of EVs and corresponding charging and energy infrastructure) rather than perpetuating ‘just-in-case’ provisioning, often based on a homogenous fleet. The upfront cost of EVs is a powerful driver in this regard. Once a right-sized fleet is in place, which may well comprise a mix of vehicles matched to a variety of duty cycles, digital solutions can be employed that aggregate multiple touchpoints of data, providing invaluable insights that can make any commercial fleet more productive and profitable.

Sounds easy?

No longer so easy! Solutions historically available to ICE fleet managers ranged from basic GPS vehicle tracking software to fully integrated driver behaviour solutions. EV fleets introduce new factors like EV range variations, charge point and power availability that require managing. The coupling of vehicle hardware and associated software solutions with charger hardware and associated software solution requirements further increases the complexity for orchestration. Adding to that site energy capacity constraints and possible competition with other site electrical energy demands, and the need for synchronisation of EV specific tasks with vehicle allocation, warehouse and yard management becomes clear.

“Holistic” and “End-to-End”

The words “holistic” and “end-to-end” are ubiquitous in discussions around electrification. But what does this actually mean?

- Some vehicle OEMs are offering an eco-system approach including chargers and vehicle telematics. However, the features are typically limited, and their offers are often tied to their products.

- Most charge point manufacturers, back-office specialists & charge point operators have access to EV charger management platforms that can do some form of simple smart charging and charger health monitoring. However, they typically lack meaningful integration with vehicle telematics or logistics systems.

- Telematics vendors have EV offers that tend to be simple systems extending only to tracking state of charge and location. Some do integrate with diesel fleet telemetry to highlight feasible vehicles for transition, but there is almost no charge point integration or coupling to logistics systems, and smart charging and vehicle allocation are also not part of their offer.

- Some energy suppliers offer smart charging and charger back offices, often as a white labelled variant of one of the above systems. Typically, no vehicle or operational integration is offered, and the offer is usually tied to an energy supply agreement.

So, it can be seen that an interpretation of where the ‘ends’ are set is needed to understand the scope of solutions that claim to be “end-to-end”. Often such an offer covers vehicle and charger only, and then in a limited fashion, leaving fleet managers with a data integration and assimilation problem rather than a solution.

So which version of end-to-end works?

The greatest value to a fleet operator lies in an ability to leverage tried and tested enterprise systems, for example embedded telematics and fleet management systems, by aggregating them with ‘new’ functionality required for an electrified fleet operation. It is the aggregation piece that overlays all elements in EV world (and equally for a hybrid model during the period of transition) that can deliver unity, agility, efficiency and real-time alerts and performance indicators in this new operating landscape. Sophisticated machine learning solutions using big data are required to achieve this, which in turn allow future iterations to be modelled that produce a virtuous circle of operational and energy efficiency:

Conclusion

To maximise transition upside, build positive PR and stay competitive, fleet managers can employ data driven solutions to take power into their hands without sacrificing other systems or processes. FPS Operate addresses the broader, more strategic decision making required to exploit the capital and operating efficiency opportunities of electrification.